Course on Fluid Power Engineering

About Course

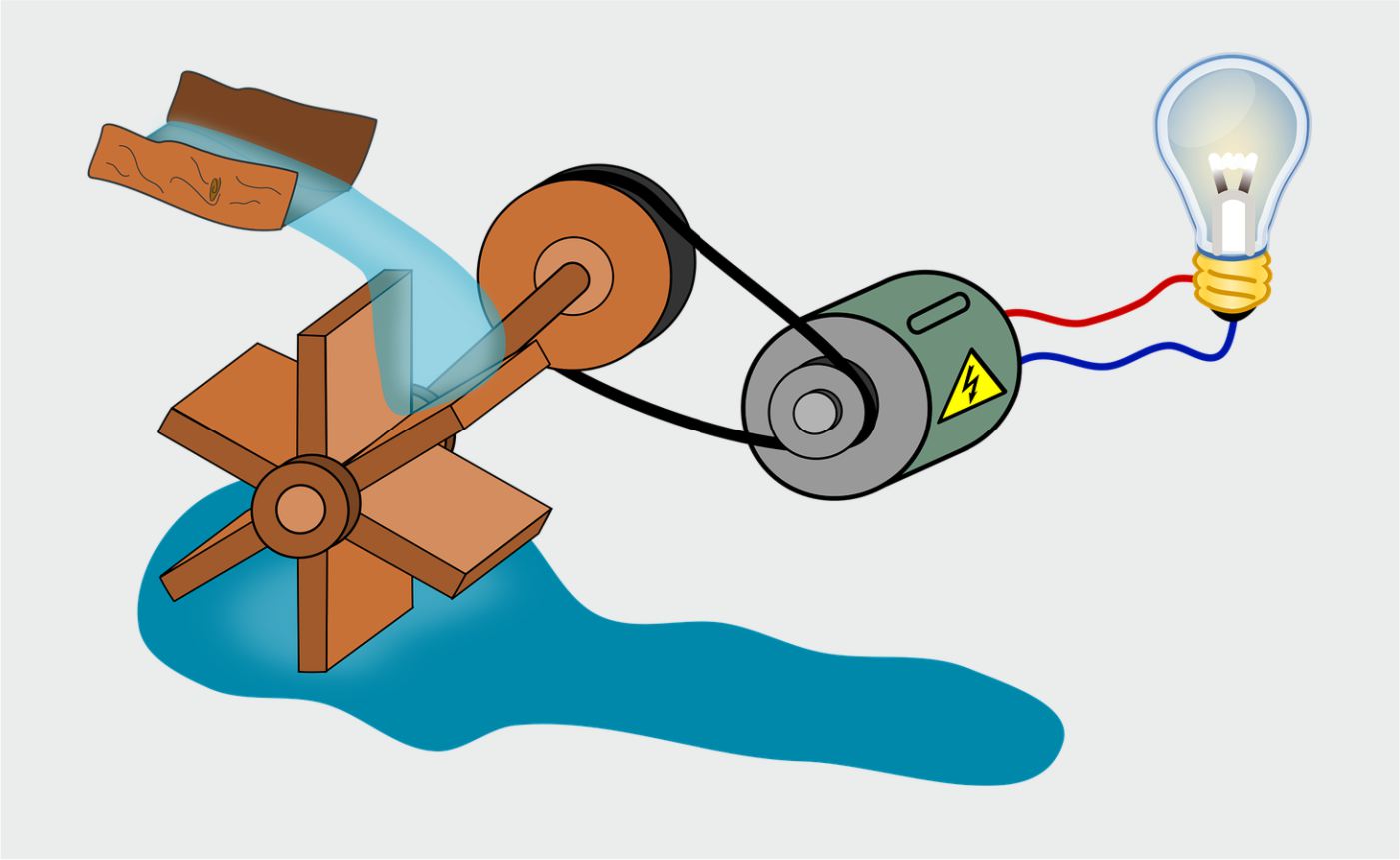

Fluid power is the use of fluids at a temperature under pressure to generate, control, and transmit power for industrial machinery. Fluid power is subdivided into hydraulics using a liquid such as mineral oil or water, and pneumatics using a gas such as air or other gases.End use industries range from plastics working to paper production. Applications include metalworking equipment, controllers, automated manipulators, material handling and assembly equipment. Fluid power systems offers important advantages over the other technologies as it can generally transmit equivalent power within a much smaller space than mechanical or electrical systems can, especially when extremely high force or torque is required since it transmit and control power through use of a pressurized fluid (liquid or gas) within an enclosed circuit. Types of symbols commonly used in drawing circuit diagrams for fluid power systems are pictorial, cutaway and graphic.This course focuses on defining various devices that forms the hydraulic systems,their working principle, application and fluid technology involved in accomplish the functions.

Course Content

Introduction to fluid power systems

-

Introduction to fluid power systems Fluid power system: components, advantages and applications. Transmission of power at static and dynamic states. Pascal’s law and its applications.

-

Fluids for hydraulic system: types, properties, and selection. Additives, effect of temperature and pressure on hydraulic fluid. Seals, sealing materials, compatibility of seal with fluids. Types of pipes, hoses, and quick acting couplings. Pressure drop in hoses/pipes. Fluid conditioning through filters, strainers; sources of contamination and contamination control; heat exchangers.

Pumps

Actuators

Components and hydraulic circuit design Components

Pressure control valves, Flow Control Valves

Hydraulic Circuit Design

Introduction to Pneumatic systems

Pneumatic Actuators

Pneumatic Control Valves

Pneumatic control circuits: Simple Pneumatic Control

Signal Processing Elements

Multi- Cylinder Application

Electro- Pneumatic Control

Student Ratings & Reviews